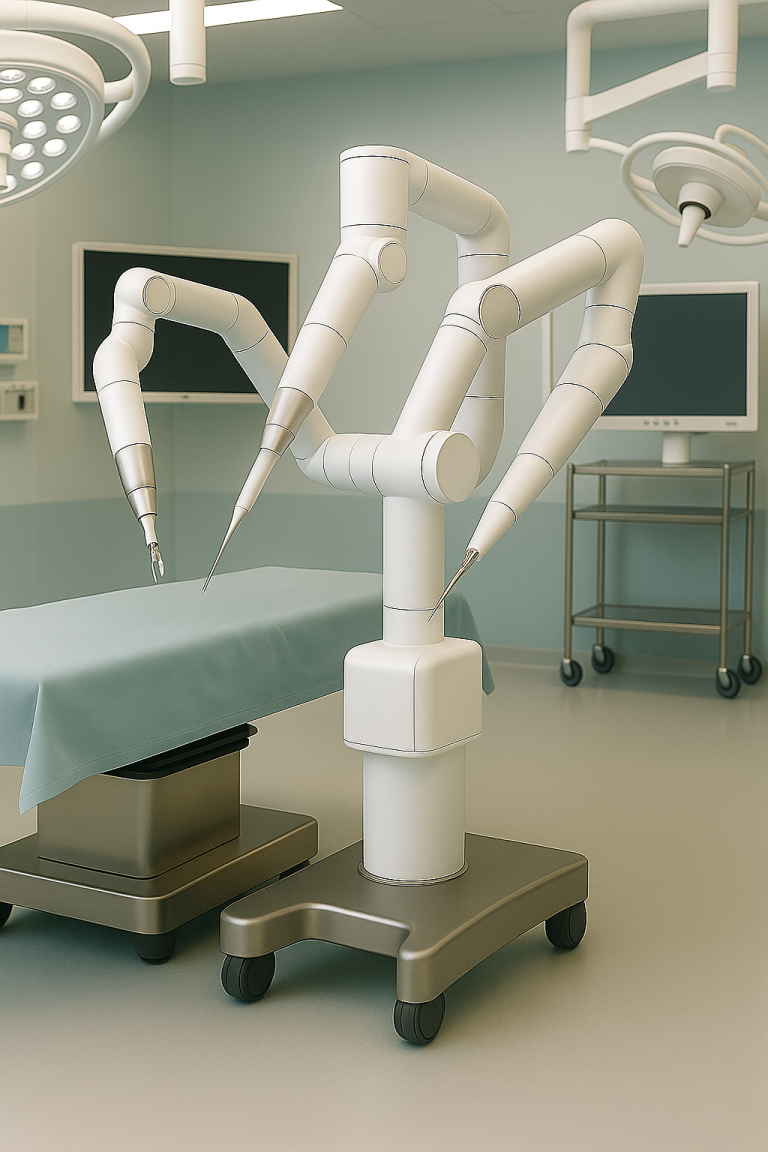

As surgical robotics continues to revolutionize the medical field, Banner Medical, a division of A. M. Castle & Co. stands at the forefront as a trusted supplier of high-performance metals and advanced processing services for surgical robotic component manufacturers and OEMs. Our extensive inventory, technical expertise, and precision value-added services support the development of robotic surgery parts, medical CNC precision parts, and complex robotic systems used in today’s most advanced operating rooms.

The attachments on robotic arms—known as end effectors—are designed to replicate the functionality of traditional surgical tools such as needle drivers, graspers, scissors, vessel sealers, staplers, and cautery instruments, but at a much smaller and more exacting scale. These critical components demand reliability, repeatability, and biocompatibility.

A. M. Castle & Co. through its various divisions supplies a broad inventory of metals suitable for the manufacture of surgical robotics and instruments, including:

Known for high strength-to-weight ratios and corrosion resistance—ideal for housings, arm joints, and support components.

These alloys offer the toughness and corrosion resistance required for repeated sterilization and use in high-precision surgical tools like suturing devices and clip appliers.

Strong and formable, often used in structural elements and custom enclosures for robotic carts and consoles.

In the medical sector—especially in robotic-assisted surgery—there is no room for error. Even the smallest material inconsistency or dimensional variation can impact device performance, surgical outcomes, or patient safety. That’s why A. M. Castle & Co. brings unmatched precision to every product and service we deliver.

Our full suite of value-added services supports OEMs and robotic surgery manufacturers from prototyping to full-scale production:

We supply the metals to the manufacturers, who develop the complete range of surgical robotic components, including:

Whether you’re designing orthopedic robotic systems, spinal implants, or next-generation surgical instruments, A. M. Castle & Co. provides the materials, services, and precision necessary to meet the challenges of modern medicine.

Let’s build the future of surgical robotics—together.

Contact our team today to discuss how our precision metals and processing capabilities can support your next project in robotic-assisted surgery.