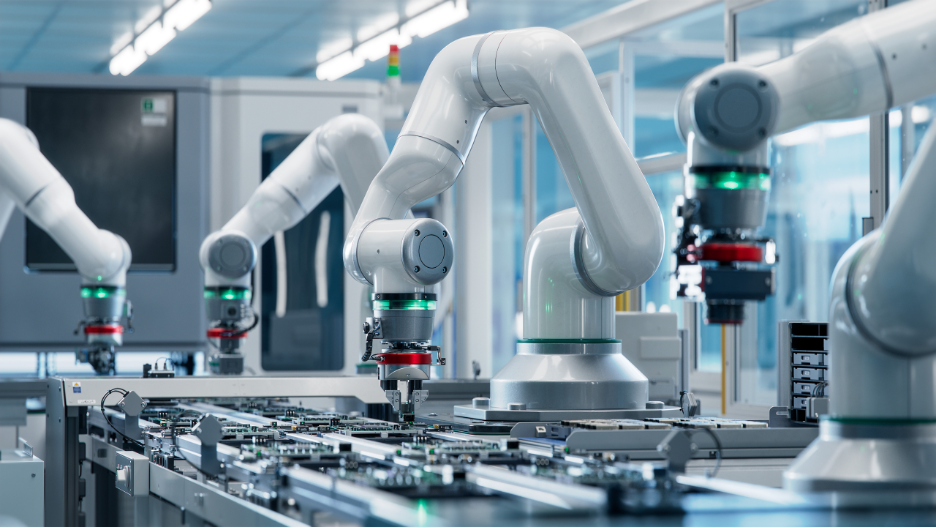

Boston, Massachusetts is a global leader in robotics, automation, and advanced manufacturing. From medical robotics and industrial automation to aerospace and semiconductor production, high-tech industries in Boston demand materials with precise tolerances, exceptional strength, and long-lasting durability.

One of the most essential materials for high-precision mechanical systems is precision ground bar stock. These bars provide superior straightness, roundness, and surface finishes, making them ideal for robotic actuators, medical devices, and linear motion systems.

As the leading precision ground bar supplier in Boston, Massachusetts, A. M. Castle & Co. provides high-performance ground bar stock for use in robotics, medical technology, semiconductor manufacturing, and industrial automation. Below, we are going to explain how precision ground bars support cutting-edge applications in high-tech industries.

Precision ground bars undergo high accuracy grinding processes to achieve tight dimensional tolerances, enhanced surface quality, and improved mechanical properties. These qualities make them indispensable in motion control systems, robotic assemblies, and automated production lines.

✔ Superior Dimensional Accuracy – Ensures consistent fit and function in high-precision components.

✔ High Surface Finish Quality – Reduces friction and wear, enhancing efficiency in robotic motion.

✔ Exceptional Straightness and Roundness – Guarantees smooth linear motion in actuation systems.

✔ Durability Under High-Stress Conditions – Withstands heavy loads and repetitive movement in industrial settings.

When acquiring materials that will be used for robotics, medical applications, and semiconductor fabrication, you’ll want to partner with a precision ground bar supplier in Boston, Massachusetts that has strict quality control processes in place. After all, even the smallest deviation can lead to system inefficiencies.

Choosing the right material composition for precision ground bars is crucial for reliability and efficiency in robotic and automation applications.

✔ Corrosion-resistant and biocompatible – Ideal for medical devices, cleanrooms, and food processing automation.

✔ Used in surgical robotics, pharmaceutical automation, and lab instruments.

✔ High-strength, wear-resistant – Suitable for robotic arms, industrial actuators, and machine tools.

✔ Common in manufacturing automation, CNC machining, and heavy-load applications.

✔ Enhanced mechanical properties for high-stress applications.

✔ Ideal for semiconductor wafer transport systems, robotic welding arms, and high-speed automation.

Precision grinding enhances the dimensional accuracy and surface quality of ground bars, improving performance and longevity in robotic systems.

✔ Reduces Friction & Wear – Improves efficiency in motion-controlled robotic arms.

✔ Ensures Consistent Motion – Eliminates vibration or uneven movement in linear guide rails and actuators.

✔ Enhances Load-Bearing Capacity – Extends the lifespan of high-load industrial robots.

By partnering with a reputable precision ground bar supplier in Boston, Massachusetts, your business can benefit from smoother automation, higher accuracy, and longer-lasting machine components.

Boston’s robotics, medical, and high-tech industries require precision-machined materials to ensure accuracy and efficiency in automation, semiconductor production, and medical robotics. As a trusted precision ground bar supplier in Boston, Massachusetts, A. M. Castle & Co. delivers high-performance ground bar stock tailored for advanced manufacturing applications.

Contact us today at (800) 289-2785 to learn more about our precision ground bar solutions.